Over the years, the lighting industry has seen its fair share of changes, but the 2025 U.S. tariff increase has created a bigger impact than just a temporary shake-up. After Trump’s introduction of sky-high tariffs on China, the situation is dire. It is a clear wake-up call. If you depend on one country or supplier, think again.

The industry has been talking about diversifying supply chains for years, but recent events have pushed lighting manufacturers, distributors, and developers to take action. What was once considered a future plan is now a crucial necessity for survival.

Why China Has Been the Number #1 Choice for Lighting Manufacturing

China has been ruling the lighting industry for a long time, and there are some good reasons why. They don’t just build components but can mass-produce cost-effective lighting solutions.

And it’s not just about cheap labor China has a complete supply chain, skilled workers, specialized factories, and the ability to quickly scale up production.

So, when the U.S. imposed a 104% tariff on lighting imports from China, the effects were immediate and dramatic. The panic caused the prices to double overnight, and importers were left in a tough spot. Suddenly, relying so much on China for the supply chain seemed risky and it all fell apart.

It wasn’t just China that was affected. Other countries like Vietnam, India, and Malaysia also faced tariff pressures, leaving the lighting industry searching for other options.

The Shift from Talk to Action

We’ve all seen that, up until now, supply chain diversification was more of a checklist item than a top priority. But the 2025 tariff increase changed EVERYTHING.

The lighting companies that only focused on cutting costs and were working on tight profits are now sitting with their heads in their hands. Diversifying the supply chain isn’t just about finding cheaper suppliers anymore it’s about survival. To stay afloat, you must reduce risks to make sure the business keeps running smoothly.

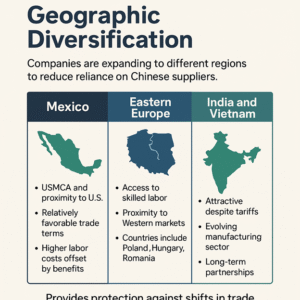

1. Geographic Diversification

The first step is expanding to different regions. Companies are moving away from relying too much on Chinese suppliers by looking for new manufacturing locations in places like:

Mexico: Thanks to the USMCA, being close to the U.S., and favorable trade terms, Mexico is a strong option for nearshoring. Even though the labor costs are higher than in China, companies can still benefit from faster shipping, better control over logistics, and fewer tariff issues.

Eastern Europe: Second on the priority list could be countries like Poland, Hungary, and Romania. They offer skilled workers and easy access to Western European markets, making them appealing for U.S. companies that want to serve both Europe and the U.S.

India and Vietnam: Even though tariffs affect these countries too, they still offer potential because of their growing manufacturing industries.

2. Multi-Tier Supplier Strategies

While it is wise to diversify across countries, true strength comes from having multi-tier supply chain strategies. This means you must build connections with:

| Strategy | What it Means | Why it’s Good |

| Multiple Main Suppliers | Getting parts from different companies in different countries. | Less risk of running out of parts, possibly better prices. |

| Backup Local Suppliers | Having local companies ready to supply if the main ones can’t. | Extra security in case of problems with main suppliers, faster local response. |

| Flexible Factories | Using different factories that can take orders depending on the situation. | Easier to adjust production based on costs, speed, and factory availability. |

This approach helps lighting companies stay flexible, adjusting production and sourcing plans when situations change.

3. Investing in Supply Chain Visibility and Technology

The increased focus on smarter supply chain systems is a major change. Because trade dynamics are unpredictable, lighting companies are using advanced logistics tools to monitor their supply chains in real time.

By using AI-powered software and IoT-based logistics platforms, companies can now:

Predict delays and shipping issues.

Track the movement of raw materials and inventory in real time.

Reroute supplies based on cost or urgency.

Improve freight and warehouse operations.

These tools help supply chain teams anticipate and solve problems before they happen. This is crucial because even a minor delay can have a big impact on projects, prices, and business relationships.

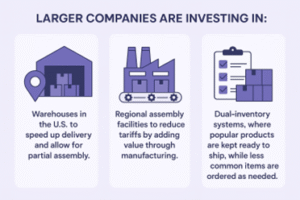

4. Rethinking Inventory and Warehousing Models

The “just-in-time” inventory model, which was once popular for its efficiency, is rapidly losing favor in the lighting industry. With tariffs, port delays, and price increases becoming more unpredictable, companies have realized that keeping low inventory can be risky.

Now, many lighting brands are shifting to a “just-in-case” strategy, which involves stocking up on essential parts in domestic warehouses and distribution centers.

Larger companies are investing in:

Even though this strategy may involve higher upfront costs, it ensures a more reliable supply and reduces risks in an uncertain market.

5. Redefining “Made in America”

While fully bringing manufacturing back to the U.S. is still difficult for many companies, the meaning of “Made in America” is changing.

Some companies are bringing some of their manufacturing back to the U.S. by doing the final steps, like assembly, packaging, or testing, in the U.S. This helps lower tariff costs and meets the growing demand for products that are at least partly made in the U.S.

Lighting companies are also working with trade experts to understand the rules of origin, find tariff exemptions, and create supply chains that are both compliant and cost-effective.

6. The Cost of Inaction: A Lesson for SMEs

For small and mid-sized lighting companies, the 2025 tariff shock was more than just a setback it was a critical challenge. These businesses often don’t have the resources or flexibility to adjust quickly. Without backup suppliers or extra storage options, many are now facing tough decisions, such as:

Delaying or canceling projects

Raising prices and risking losing customers

Absorbing extra costs and operating at a loss

Considering layoffs, mergers, or shutting down

For these companies, diversifying is crucial. Delaying diversification only makes it harder and more expensive. Industry leaders are advocating for collaboration and knowledge-sharing to help smaller companies become more resilient.

The Future Belongs to the Flexible

The main point is that depending too much on one country for supplies is dangerous. Today’s world is unpredictable, and that risk is too big.

Lighting companies that start diversifying their supply chain now will be more stable in the long run. They will also gain greater customer trust and be able to adapt to future problems more quickly. Those who don’t diversify might lose out on more than just price – they could fall behind in every aspect of their business.

At Lighting and Supplies, we know how important it is to have dependable, diverse, and affordable lighting solutions. As a trusted supplier of lighting solutions, we’re here to help businesses overcome these challenges and stay ahead of the curve.

If you’re ready to make your business future-proof with smart lighting solutions, get in touch with Lighting and Supplies today. Find out how we can help you stay flexible and resilient in your supply chain.